7/24 Operations

The Hangar Door for crane way has excessive durability although it is not expected cause of big body our hangar doors can be operated 7/24 specially choose high resistance fabric and gearbox system supply continuously operation at required.

Excellent Sealing

Only our doors have side sealing pocket instead of all other fold up doors. This heavy duty PVC coated fabric supplies excellent sealing when doors is closed even high windy conditions. It has also special cover space between crane rails and doors so it is a result of unique design of door.

This design also supplies noiseless operations.

Low Maintenance

Crane hangar doors have no need any special maintenance all parts is carefully chosen for no maintenance requirements.

Maximum Dimensions

Crane hangar doors don’t have any limit for dimensions to cover T shape of crane way. Maximum height is 40 mt and width is 40 mt.

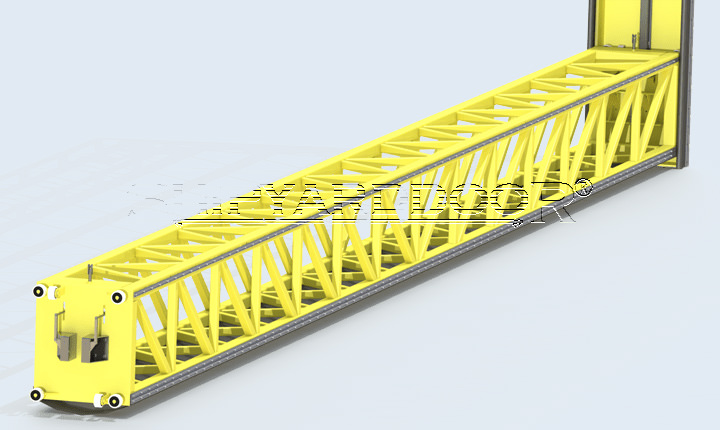

Steel Structure

Doors are made of two fabrics folding in opposite directions. Fabric sections are fastened to horizontal beams (Steel or aluminum). Minimum door thickness is 600 mm that is our special properties. Intermediate beams are retractable by means of an electric motor. The beams have tires for easy operations at windy conditions. The intermediate beams when retracted don’t impede the clear opening dimensions.

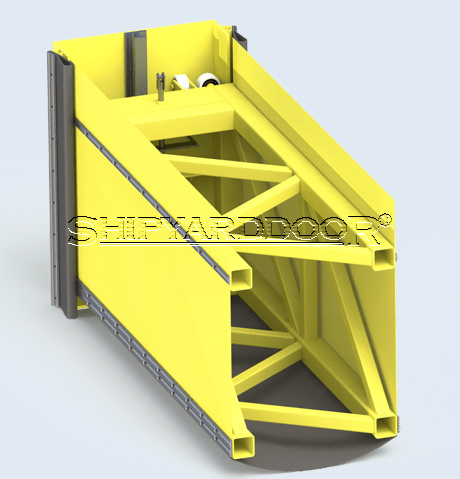

Bottom Beams

Bottom beam is designed according to wind resistance, dimension of the doors and, to carry load of the intermediate steel beams during door operations. Bottom beam also supply full closing and sealing in heavy wind conditions.

Side guides

Shipyarddoor Flexible Giant® vertical guides are made of structural steel with a suitable depth and width dependent on the size of the intermediate beams. Guides is designed to provide weather-sealing between the door and door frame.Opposite our competitors Shipyarddoors supply side guide rails with steel support parts,side guides are designed and manufactured easily replaceable in case of damage.Aluminum rails fixed with bolt to steel structure

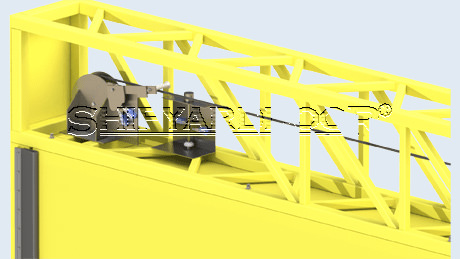

Cable System

Shipyarddoors are operated with steel cable,maximum of two cable each doors that running inside of the door guides. Cables are installed free of any kinks and the system design and sheave diameter is choosed carefully such to prevent the occurrence of any kinks or abnormal stress in the operating cables.Sheaves can be inspected easly by technicans

Fabric

Specially choose fabric is suitable for long life. İt have very high resistance against to UV damage, VALMEX POLYMAR ® industrial Fire resist 900-1500 gr/m2 2 mm 1100 Dtx B 6000

Tensile Straight 4300/4000 N/50 mm DIN 53354.

Tear Strength 500/500 N DIN 53363

Fire Resistance

Fire resistance of the fabric is suitable for any fire safety regulations . Relative Standard is DIN 4102-B1.These materials are difficult to ignite. They include materials such as wood treated with a fire retardant and rigid foam plastics. A fire must extinguish itself when the source of the fire is removed.

Sealing

The bottom beam is furnished with cellular rubber seal(U-Shaped). The side guides on frame structures or mullions have either cellular rubber seals or integral brush seals depending on door type.Specially choosed rubber has high resistance aganist to outdoor conditions extreme cold and hot weather.

Insulation Data

Standard Shipyarddoor Flexible Giant fold-up hangar Doors has excelent insulations cause of its extreme width and sealing properties. termal insulation value U<0.9 W/m2.K Isolated fabric also avalible Sound attenuation 12 dB A.

Wind Resistance

Shipyarddoor ® hangar door is designed as a unitary system to withstand wind load specified. Fiber stresses due to combined dead load and wind load will not exceed factors for the material being used and type of loading sustained,operationally 140 km /h also at closed positions can be stand up to 180 km/h. Special conditions can be manufactured up to 230 km/h hurricane standard.

Structural Loading

Shipyarddoor® hangar door is designed withstand dead load, seismic forces and design loads due to pressure and suction of wind calculated in accordance to envorimental and bulding ambient

Driving Unit and limit switches

All driving units and component choose for resistance of extreme conditions in Mining area .The lifting motors are normally located above the door opening. All Shipyarddoor hangar doors are equipped with double motor to supply balanced uplift and even though if 1 motor damaged other can operate the system. The limit switches are also located above door opening. Shipyarddoor switch system doesn’t miss or damage, all switches are located both sides with safety switch. The door stops on the limit switch when the door is completely opened or completely closed. Should the doors by-pass these limit switches there are also safety limit switches in both directions. In upward direction the limit switches are located above door. At each end of door and topmost moving horizontal door beam will activate them. In downward direction limit switches are located above door opening on slack strap/rope switches.

Speed

Hangar Doors is operated as a standard 20 cm /sec opening and closing speed also it is can be increased up to 40 cm/sec .

Safety

All doors is manufactured CE Standard Applicable Directives 89/106/EC-99/93/E Applicable Standards: - EN 13241-1:2003+A1:2011-EN 12978:2008 andermic résistance, buzzer and warning light is served as a standard Optionally pneumatic safety edge system is available.

Operations

Shipyarddoor® Flexible Giant fold up fabric hangar door is guide up and down in the weather sealing vertical guides attached to the structure. Door is controlled by three buttons marked “Open,” “Closed,” and “Stop.” Audible and visual warning devices is started automatically signal for a few seconds before any door section movement, remain continuously on while the door is in motion and reset immediately after movement stops.

Manual Operations;

There are a few ways the emergency operation could be accomplished.

- A hand crank that attaches to the output shaft of the motor is available for manual operation. In cases of very large oors, this is not a feasible way of opening the door.(is avaliable)

- Connecting the door to a power generator would eliminate the problem in case of a power failure.

Color

Wide range fabric color is available ,All main color at our stock (RAL 9002-9006-1001 -3001 – 5007-6001-7071) (some color is out of stock can be extend delivering time)

Control panel

Control board is designed according to CE 2006/95 EC and to NEMA ICS 6, Standard. İt is specially desing for simple and high durability not included very expensive swicth board -PLC- or equipments.

As a part of safety requlations Control panel is also contain interlocks to preclude personnel injury,key lock for autorised personal operations and including an interlock between the power supply system and use of the hand crank for manual operation of door unit.(Optional)It is controlled by momentary pressure to open and constant pressure to close , also Dead-Man mode is avalible.

Optionally;

- Control panel can be also contain -Frequency converters , Safety Edge System. PLC Controller with touchless button.

- Control panel can be fed from an automatic transfer switch which will supply emergency power to the door systems in case of a power failure.